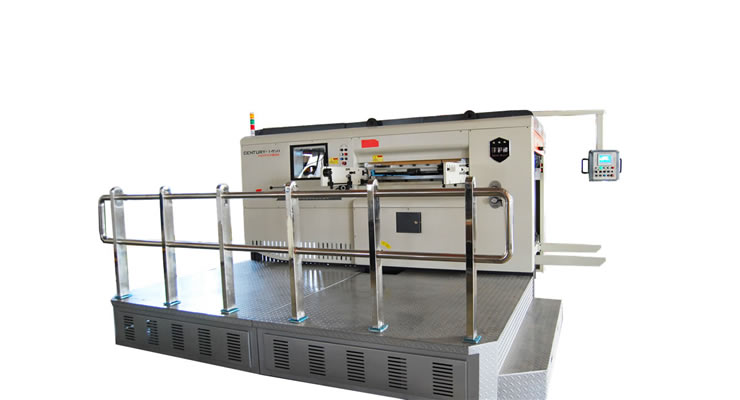

Semi-automatic Flatbed Die Cutting Machine, MWB Series

This product has been discontinued and removed from our shelves.

The semi-automatic die cutters are Century's best-selling product. They are designed for conversion of paper, corrugated board, PP materials, especially for curved boards.

Processed Materials

Suitable for the following industries

Packaging: corrugated board, paper board and PP boxes

Packaging: corrugated board, paper board and PP boxes

Features of MWB Series semi-automatic flatbed die cutting machine include

CE certified

Human machine interface

Siemens latest PLC technology

Wide stock range of paper converting

Photo-electrical device for safe operation

European, Taiwanese and Japanese standard spare parts

ISO9001:2008 approved manufacturing process.

Specifications

MWB 930

| Model |

MWB 930 |

| Maximum paper size |

960*680mm |

| Minimum paper size |

400*360mm |

| Maximum cutting size |

930*660mm |

| Maximum cutting pressure |

150 T |

| Stock range |

Corrugated board up to7mmand Cardboard >250gsm |

| Cutting precision |

±0.5mm |

| Maximum speed |

4,200 s/h |

| Pressure adjusting range |

±1mm |

| Minimum front waste |

8mm |

| Inner chase size |

960*700mm |

| Machine dimension (L*W*H) |

4910*3705*2045mm |

| Total power |

11 KW |

| Machine's weight |

9 T

|

MWB 1050

| Model |

MWB 1050 |

| Maximum paper size |

1080*780mm |

| Minimum paper size |

400*360mm |

| Maximum cutting size |

1050*760mm |

| Maximum cutting pressure |

200 T |

| Stock range |

Corrugated board up to7mmand Cardboard >250gsm |

| Cutting precision |

±0.5mm |

| Maximum speed |

4,200 s/h |

| Pressure adjusting range |

±1mm |

| Minimum front waste |

8mm |

| Inner chase size |

1080*790mm |

| Machine dimension (L*W*H) |

5390*4180*2165mm |

| Total power |

13 kw |

| Machine's weight |

10.5 T

|

MWB 1160

| Model |

MWB 1160 |

| Maximum paper size |

1180*900mm |

| Minimum paper size |

450*400mm |

| Maximum cutting size |

1160*880mm |

| Maximum cutting pressure |

200 T |

| Stock range |

Corrugated board up to7mmand Cardboard >250gsm |

| Cutting precision |

±0.5mm |

| Maximum speed |

4,200 s/h |

| Pressure adjusting range |

±1mm |

| Minimum front waste |

8mm |

| Inner chase size |

1190*910mm |

| Machine dimension (L*W*H) |

5610*4300*2285mm |

| Total power |

13 kw |

| Machine's weight |

12 T

|

MWB 1300

| Model |

MWB 1300 |

| Maximum paper size |

1330*980mm |

| Minimum paper size |

550*480mm |

| Maximum cutting size |

1300*960mm |

| Maximum cutting pressure |

250 T |

| Stock range |

B, C, A flue and double wall, Corrugated board up to9mm |

| Cutting precision |

±0.5mm |

| Maximum speed |

4,200 s/h |

| Pressure adjusting range |

±1mm |

| Minimum front waste |

8mm |

| Inner chase size |

1330*990mm |

| Machine dimension (L*W*H) |

6120*4615*2290mm |

| Total power |

16.5 kw |

| Machine's weight |

15 T

|

MWB 1450

| Model |

MWB 1450 |

| Maximum paper size |

1480*1080mm |

| Minimum paper size |

480*550mm |

| Maximum cutting size |

1450*1050mm |

| Maximum cutting pressure |

300 T |

| Stock range |

B, C, A flue and double wall, Corrugated board up to9mm |

| Cutting precision |

±0.5mm |

| Maximum speed |

4,000 s/h |

| Pressure adjusting range |

±1mm |

| Minimum front waste |

8mm |

| Inner chase size |

1480*1080mm |

| Machine dimension (L*W*H) |

6330*4900*2350mm |

| Total power |

20.5 kw |

| Machine's weight |

17 T

|

MWB 1620

| Model |

MWB 1620 |

| Maximum paper size |

1650*1210mm |

| Minimum paper size |

550*650mm |

| Maximum cutting size |

1620*1190mm |

| Maximum cutting pressure |

300 T |

| Stock range |

B, C, A flue and double wall, Corrugated board up to9mm |

| Cutting precision |

±0.5mm |

| Maximum speed |

3,600 s/h |

| Pressure adjusting range |

±1mm |

| Minimum front waste |

10mm |

| Inner chase size |

1646*1220mm |

| Machine dimension (L*W*H) |

6620*5330*2550mm |

| Total power |

21 kw |

| Machine's weight |

21 T

|

Features of machine include

Feeding Section

Feeding Section

Effective manual feeding system.

Automatic sheet pile lifting system.

Side guide to position paper pile center.

Die Cutting Section

Die Cutting Section

A pneumatic push button die-chase locking mechanism is used to ensure a safe and operator friendly changing of cutting die.

Using internationally known bearings and electronic components, precise control of the die cutting process is achieved.

Delivery Section

Delivery Section

Optional function:Tape inserter.

Side and front joggers to ensure neat stacking.

Two delivery options available: pallet or trailer.

Photoelectric detective device for safety entrance and operation.

Electrical Control Section

Electrical Control Section

The electrical control section uses the latest PLC technology for trouble free operation.

This die cutting machine also uses electrical components from internationally known companies for a better performance and quick, efficient, local after-sales service and maintenance.

The semi-automatic die cutting machine is equipped with a number of safety protection devices. The machine will alarm and stop automatically when faults occur.

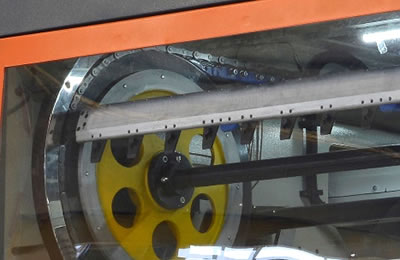

Main Drive Chain

Main Drive Chain

Heavy load and a highly precise chain achieve a high tensile strength and wear resistance.

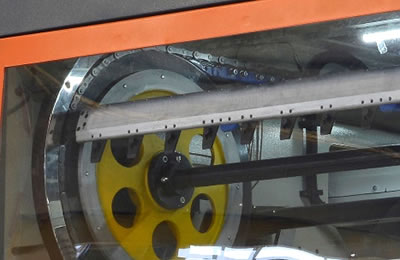

Main Driving System

Main Driving System

A mono-block casting chassis is used to reduce the vibration and achieve a better performance and a longer lifespan.

A deepened oil tank to make part of worm wheel working under lubrication oil for better lubrication.

Packaging: corrugated board, paper board and PP boxes

Packaging: corrugated board, paper board and PP boxes Feeding Section

Feeding Section Die Cutting Section

Die Cutting Section Delivery Section

Delivery Section Electrical Control Section

Electrical Control Section Main Drive Chain

Main Drive Chain Main Driving System

Main Driving System